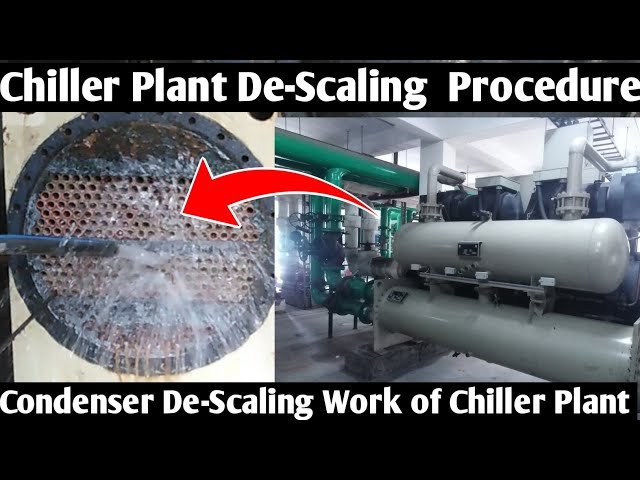

When and How to De-Scale a Chiller Condenser: Key Considerations and Precautions

How often the condenser of the chiller must be de-scaled and how can we determine that now it is necessary to do de-scaling of the condenser? What are the factors to consider and be taken into account during the de-scaling of the condenser?

The water quality and conditions usually determine the de-scaling of the condenser in a chiller system. Nonetheless, in most cases it would be advisable to do a check up and cleaning of the condenser once a year and possibly more often in instances where the water would be rich in minerals like in the event whereby one lives in an area that has hard water.

Symptoms indicating that the Condenser Requires De-scaling:

1. Decreased Effectiveness in Cooling: Decreased efficiency in cooling procedures: A decrease in efficiency of the chiller or a longer period of time to cool to the required temperature could be an indication of impediment to dissipation of heat due to scaling.

2. Poor Heat Exchange: Scaling results in poor heat exchange and this necessitates consumption of increased amount of energy to achieve the same amount of cooling produced.

3. Increased Pressure: The readings of pressure in the system may rise because of lowering heat transfer efficiency as a result of scaling.

4. Frost Build-up: Condenser: The over scaling could result in the process of condensation which could be in the form of frost or ice deposits.

5. Visual Inspection: Scaling may be evident visibly on the condenser tube where it may be seen as a deposit of mineral deposits.

Considerations and precautions when Using

De-scaling:

1. Right Chemicals: There are specific chemicals that should be used with the right descaling chemicals depending on the scale (calcium, lime, etc) being removed. Abide by manufacturer specifications of dosages and concentration of chemicals.

2. Safety Precaution: Descaling can be corrosive, take precaution by using personal protective equipment (PPE), including hooded aprons, goggles and gloves. Make the area well-ventilated.

3. System Shutdown: They should also ensure that the chiller is switched off and cooled off before starting the process of de-scaling. This will avoid injury and save the system.

4. Clean thoroughly: When the descaling solution has been applied repeat the rinsing procedure so as to flush out all chemicals left behind.

5. Leakage: Make sure that the condenser is not leaking after the de-scaling procedure is done and also check that no component is damaged.

6. Consider Manufacturer Guidelines: It is possible that every chiller system would have special guidelines of cleaning it, hence application of user manual is highly recommended.

7. Environmental Impact: Dispose of the used descaling solution in a way that takes into consideration the environmental rules.

The de-scaling should be incorporated in the regular practice to make sure that the chiller is working effectively and can last for a long duration. In case you are not sure, it sometimes pays off to consult a technician

What's Your Reaction?